UV-FCU-CL is composed of:

- Programmed switching on. It is possible to program the time of irradiation by means of an adjustable timer.

- Automatic switch-off. A safety system switches off the lamps in case of entry of personnel.

- Fault alarm. In case of failure of one or more lamps, a light on the panel will be activated.

- Hour counter. Management of the replacement of lamps about to run out of life.

- Automatic switch-off. A safety system switches off the lamps when personnel enter.

- Fault alarm. A warning light is switched on in the event of a fault.

- Hour counter. Control of the replacement of lamps about to run out of life.

UV-FCU-CL

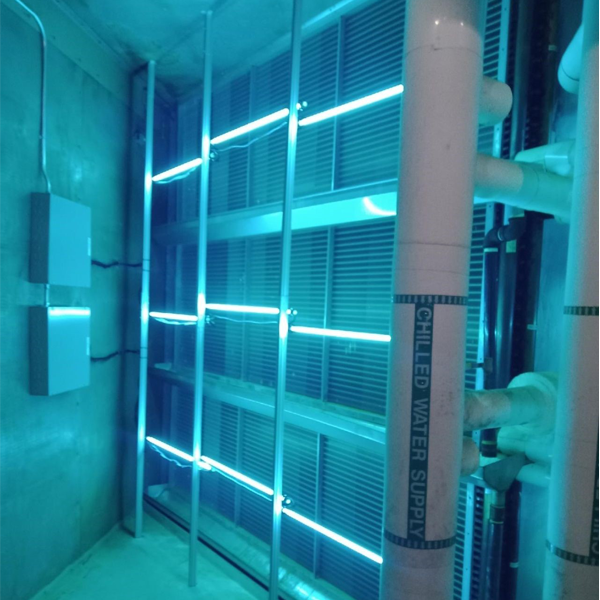

The UV-FCU-CL air disinfection system can be applied for air disinfection in fancoils and air handling units. (U.T.A).

For installation on FANCOIL it is sufficient to fix the supplied clips in the space between the fan and the heating/cooling battery; the lamp is inserted between the above sections and locked with the clips. Installation is simple and it is also possible to use it on already installed and working fan coils (re-trofit technology on already existing systems). The supplied electronic power supply unit, which is small in size, is supplied with a plug/socket connection system that simplifies lamp replacement.

For the sanitization of the air and the radiant batteries in the air treatment units (A.T.U.) the UV-FCU-CL device directly radiates, with UV-C rays, air filters and cooling and/or humidification batteries inside the A.T.U., to avoid the formation and growth of microorganisms potentially harmful to people’s health. The use of the UV-FCU-CL represents an economical and reliable solution to stop the access of microbes to social rooms or to controlled contamination chambers, through a simple installation that is safe for the personnel, since everything is limited to an irradiation inside the AHU ducts, allowing a considerable saving in management costs and health protection from infectious diseases such as:

1) Sick Building Syndrome;

2) Legionnaires’ disease (Legionella Pneumophila - typhus of legionnaires);

3). Tuberculosis (Mycobacterium Tub.)

4) Monday or humidifier fever.

DISCOVER THE PRODUCTS

UV-DUCT-FL-NX

UV-DUCT-FL-NX purifies homogeneously the airflow running through its powerful lamps, eliminating the microbial load and the spreading and distribution of hazardous and annoying pathogens inside buildings.

In AC systems an unpleasant biofilm covers usually all inner surfaces as the result of microorganisms combination and favorable conditions for their proliferation, such as temperature changes, high humidity and darkness. UV-DUCT-FL-NX inhibits the creation of this biofilm increasing Indoor Air Quality and comfort.

More specifically, the use of UV-DUCT-FL-NX eliminates important issues related to AC Systems and deadly illnesses (such as Legionella Pneumophila, Tuberculosis, Flu, etc.) but also “Sick Building Syndrome”, “Monday Fever”, Asthma and Allergies. UV-DUCT-FL-NX allows also the control of Hygiene high standards in Food industry and fights against Healthcare Associated Infections (HAI) in hospitals.

UV-DUCT-FL-NX application is important not only for IAQ and health, but a cleaner AC system is also more efficient from an economic point of view, with less operative and maintenance costs. As a matter of fact, using UVGI the need of filters replacement and clean of inner surfaces is less necessary than usual.

With UV-DUCT-FL-NX you obtain a deep and continuous disinfection and cleaning of your AC system, without the use of expensive and polluting chemicals, , in few words with UV-DUCT-FL-NX you have better comfort for people in the building, saving money.

UV-STICK-SCR / UV-STICK-SCR-UL

UV-STICK-SCR is the simplest, most flexible and more efficient device to improve Indoor Air Quality (IAQ), but also save energy consumption and maintenance costs in HVAC Systems.

Its germicidal power cleans and purifies all surfaces inside A.C., where usually an unpleasant biofilm covers and adheres on every mechanical component, penetrates inside every little interstice, grow in between coil fins, settles on water tanks and spreads freely all over the air along A.C. ducts.

Legionella Pneumophila, Tuberculosis, Flu Viruses and other common pathogens are usually free to proliferate inside HVAC, with Volatile Organic Compounds (VOCs) cause of Asthma, Allergies, the so called “Sick Building Syndrome” and “Monday Fever”. In hospitals risks increase with Cross Contamination and Healthcare Associated Infection.

UV-STICK-SCR application is important not only for IAQ, but a cleaner AC system is also more efficient from an economic point of view, with less operative and maintenance costs. As a matter of fact, using UVGI the need of filters replacement and chemical clean of inner surfaces is less necessary than usual.

Other benefits are the optimized level of energy consumption, reduction of air flow losses, in few words with UV-STICK-SCR you have better comfort for people in the building, saving money.

UV-RACK

UV-RACK purifies homogeneously the airflow running through its powerful lamps, eliminating the microbial load and the spreading and distribution of dangerous and annoying pathogens inside buildings.

in AC systems an unpleasant biofilm covers usually all inner surfaces as the result of microorganisms combination and favorable conditions for their proliferation, such as temperature changes, high humidity and darkness. UV-RACK inhibits the creation of this biofilm increasing Indoor Air Quality and comfort.

More specifically, the use of UV-RACK eliminate important issues related to AC Systems and deadly illnesses (such as Legionella Pneumophila, Tuberculosis, Flu, etc.) but also “Sick Building Syndrome”, “Monday Fever”, Asthma and Allergies. UVRACK allows also the control of Hygiene high standards in Food industry and fights against Healthcare Associated Infections (HAI) in hospitals.

UV-RACK application is important not only for IAQ and health, but a cleaner AC system is also more efficient from an economic point of view, with less operative and maintenance costs. As a matter of fact, using UVGI the need of filters replacement and clean of inner surfaces is less necessary than usual.

With UV-RACK you obtain a deep and continuous disinfection and cleaning of your AC system, without the use of expensive and polluting chemicals, , in few words with UV-RACK you have better comfort for people in the building, saving mone y.

UV-DUCT-SQ / UV-DUCT-SQ-UL

UV-DUCT-SQ is very versatile and its shape has been designed to adapt quickly to different applications; UV-DUCT-SQ is a modular system that can be mounted by itself or combined with other modules side-by-side, overlapping, etc.; it purifies homogeneously the airflow running through its powerful lamps, eliminating the microbial load and the spreading and distribution of dangerous and annoying pathogens inside buildings.

in AC systems an unpleasant biofilm covers usually all inner surfaces as the result of microorganisms combination and favorable conditions for their proliferation, such as temperature changes, high humidity and darkness. UV-DUCT-SQ inhibits the creation of this biofilm increasing Indoor Air Quality and comfort.

More specifically, the use of UV-DUCT-SQ eliminates important issues related to AC Systems such as deadly illnesses (Legionella Pneumophila, Tuberculosis, Flu, etc.) but also “Sick Building Syndrome”, “Monday Fever”, Asthma and Allergies. UV-DUCT-SQ allows also the control of Hygiene high standards in Food industry and fights against Healthcare Associated Infections (HAI) in hospitals.

UV-DUCT-SQ application is important not only for IAQ and health, but a cleaner AC system is also more efficient from an economic point of view, with less operative and maintenance costs.

As a matter of fact, using UVGI the need of filters replacement and clean of inner surfaces is less necessary than usual.

With UV-DUCT-SQ you obtain a deep and continuous disinfection of your AC system, without the use of expensive and polluting chemicals, , in few words with UV-DUCT-SQ you have better comfort for people in the building, saving money.

UV-STYLO-E

UV-STYLO-E has been designed to sanitize water directly within basins, sinks, washing systems (IP67).

Most of the time inside the tank containing the percolating water, which is used to be sprayed in the evaporative panels, there, are sedimentation of mold and algae, and the interior surfaces are covered with an unpleasant biofilm. The most risky case is that there could be also deadly pathogens such as Legionella Pneumophila, for which there are several hundred deaths cases per year.

This happens because the water sprayed inside AC system spreads airborne diseases inside buildings, through infectious particles breathable in air.

UV-STYLO-E avoid also so called “Sick Building Syndrome”, “Monday Fever”, Asthma and Allergies, it allows the control of Hygiene high standards in Food industry and fights against Healthcare Associated Infections (HAI) in hospitals. UV-STYLO-E application is important for not only IAQ and health, but a cleaner AC system is also more efficient from an economic point of view, with less operative and maintenance costs. As a matter of fact, using UVGI the need of filters replacement and clean of inner surfaces is less necessary than usual.

With UV-STYLO-E you obtain a deep and continuous disinfection and cleaning of your AC system, without the use of expensive and polluting chemicals, , in few words with UV-STYLO-E you have better comfort for people in the building, saving money.

UV-STYLO-X

UV-STICK-AX

The device is a reglette built entirely in extruded anodized aluminum, IP55 protection and fitted with a reflecting screen in mirror bright aluminum, to increase the power of radiation, through the reflection of UV-C proportion that would otherwise be wasted in the opposite direction to the useful ones.

The extruded aluminum case, contains special electronic ballasts to maximize yield and duration of UV-C lamp.

To avoid flying splinters of glass after the collapse of the UV lamp, a protection of the UV lamp by means of the special thermo-retracted sheath UVLON®-PIPE

(Tetrafluoroethylene), with UV-C transparency >85%. can be provided, always as an option UVLON®-PIPE is a patented system to withstand the wear and tear; it has low adhesion to any product or substance, is resistant to any aggressive chemical at high or low temperatures. It is a polymer conforms to F.D.A. tests for use with foodstuffs.

The constituent materials of UV-STICK...AX allow its use even in harsh operating conditions (high humidity, low temperatures, etc..), or where conditions require a high resistance to chemicals and weathering.

UV-STICK is built with high quality, extremely resistant components, it works perfectly in difficult operative conditions (high Humidity, low temperatures, etc).

UV-STICK-AX-SCR

The device is a reglette built entirely in extruded anodized aluminum, IP55 protection and fitted with a reflecting screen in mirror bright aluminum, to increase the power of radiation, through the reflection of UV-C proportion that would otherwise be wasted in the opposite direction to the useful ones.

The extruded aluminum case, contains special electronic ballasts to maximize yield and duration of UV-C lamp.

To avoid flying splinters of glass after the collapse of the UV lamp, a protection of the UV lamp by means of the special thermo-retracted sheath UVLON®-PIPE (Tetrafluoroethylene), with UV-C transparency >85%. can be provided, always as an option UVLON®-PIPE is a patented system to withstand the wear and tear; it has low adhesion to any product or substance, is resistant to any aggressive chemical at high or low temperatures. It is a polymer conforms to F.D.A. tests for use with foodstuffs.

The constituent materials of UV-STICK...AX allow its use even in harsh operating conditions (high humidity, low temperatures, etc..), or where conditions require a high resistance to chemicals and weathering.

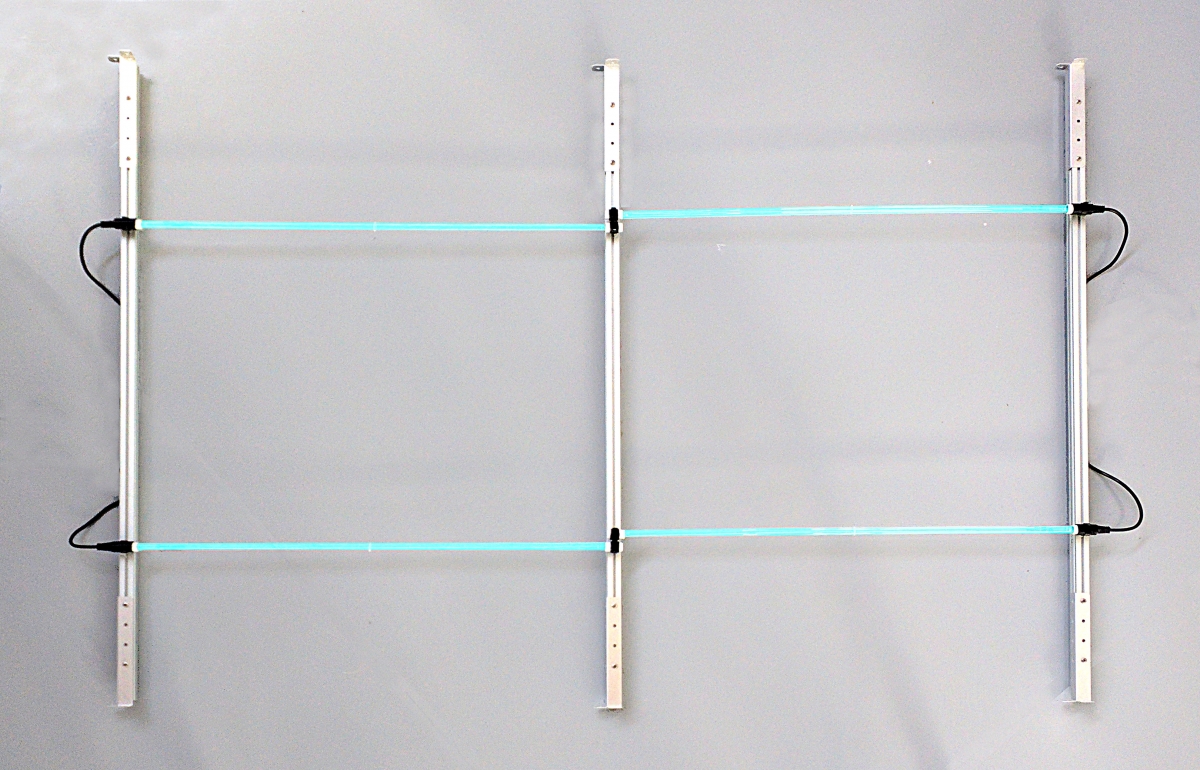

We suggest to install one or more UV-STICK…AX-SCR in a layout that allow the device/s to irradiate coil’s surface entirely, to obtain an homogenous treatment of inner surfaces.

For this reason Light Progress offers a special and adjustable mounting kit to install devices properly.

Mounting kit is made in anodized aluminum, it can be used to install devices in serie, attacching them directly to AHU’s wall.

Devices are connected through SCR serial connectors, it is possible to switch them all ON through only one power supply cable

UV-STICK-SCR is built with high quality, extremely resistant components, it works perfectly in difficult operative conditions (high Humidity, low temperatures, etc).